MU2D PROFI LW

The universal double flail mower MU2D PROFI LW is designed for demanding working conditions and large areas in agriculture.

The electronically balanced rotor with the patented Low Vib (LW) distribution of the flails ensures less vibration and minimal bending stress and deformation, extending the service life of the flail mower. Robust flails made of forged steel ensure efficient mulching by creating turbulence and vacuum.

The flail mower combines two universal flail mower units MU PROFI LW and a middle flail mower, driven by a hydro motor. The double skin housing ensures structural strength and greater durability. The two positions of the supporting roller make it easy to adapt to different user requirements. The inner position ensures faster material flow and thus enables higher working speeds, while the outer position improves the quality of mulching. The adjustable maintenance hood allows provides additional flexibility.

Tehnične skice

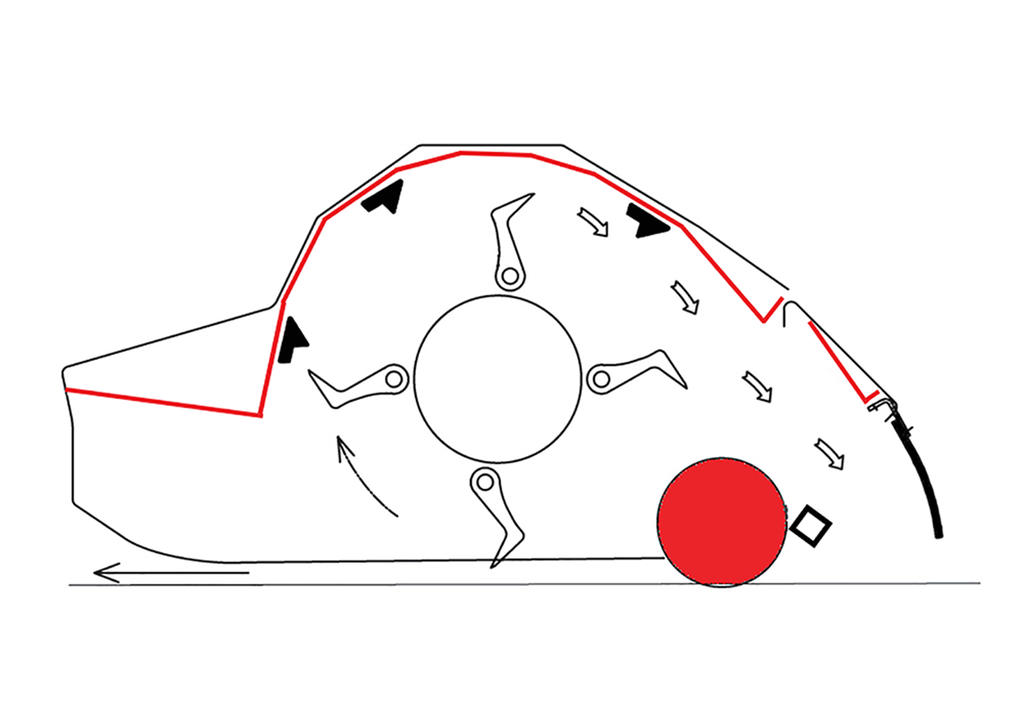

The inner position of the supporting roller

The inner position ensures faster material flow and thus enables higher working speeds.

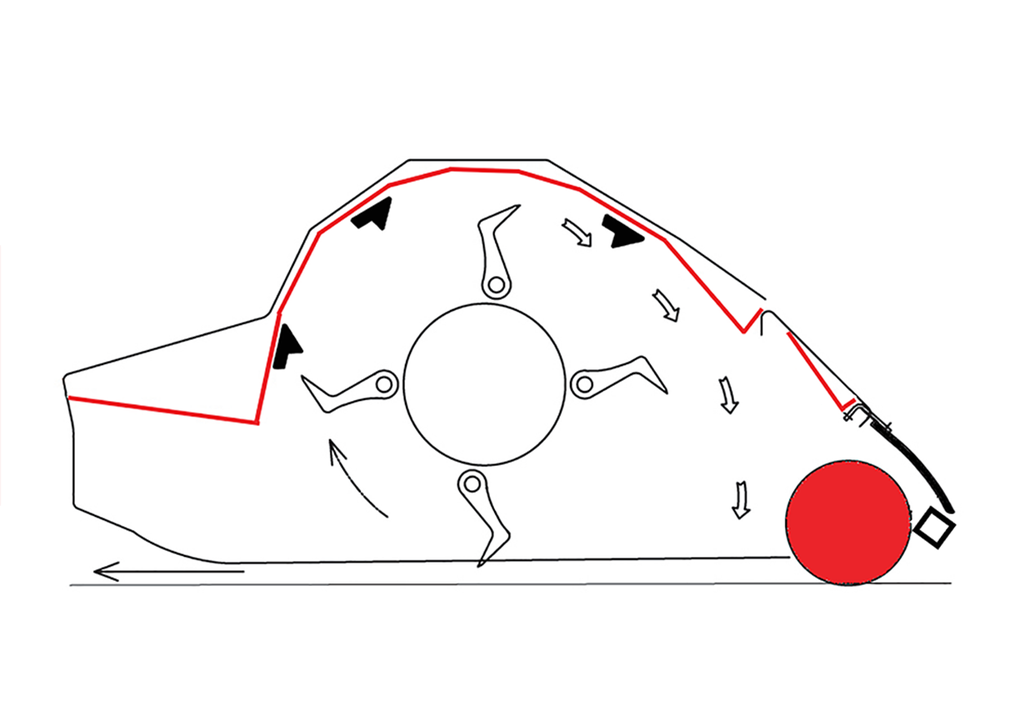

The outer position of the supporting roller

The outer position improves the quality of the mulching.

DANE TECHNICZNE

|

MU2D 610 LW

|

|

|---|---|

|

Szerokość robocza (cm)

|

610

|

|

Wymiary transportowe (AxB) (cm)

|

340x236

|

|

Pływający kąt

|

+ / - 7°

|

|

Liczba pasów (szt.)

|

2x5

|

|

Średnica wirnika (mm)

|

219

|

|

Liczba bijaków (szt.)

|

2x28

|

|

Waga bijaka (kg)

|

1,4

|

|

Podwójna obudowa

|

√

|

|

Rzędy przeciwnoży

|

3

|

|

Uchylna klapa

|

√

|

|

Moc ciągnika (kW)

|

125-200

|

|

Moc ciągnika (KM)

|

170-270

|

|

Waga maszyny (kg)

|

3030

|

DANE TECHNICZNE

MU2D 610 LW

610

Szerokość robocza (cm)

219

Średnica wirnika (mm)

170-270

Moc ciągnika (KM)

3030

Waga maszyny (kg)

Robustna konstrukcija, vsestranska funkcionalnost in dolga življenjska doba.

Standardna oprema1 test

- Rotor with patented Low Vib (LW) distribution of the flails

- High-quality double skin housing

- Middle mulching unit

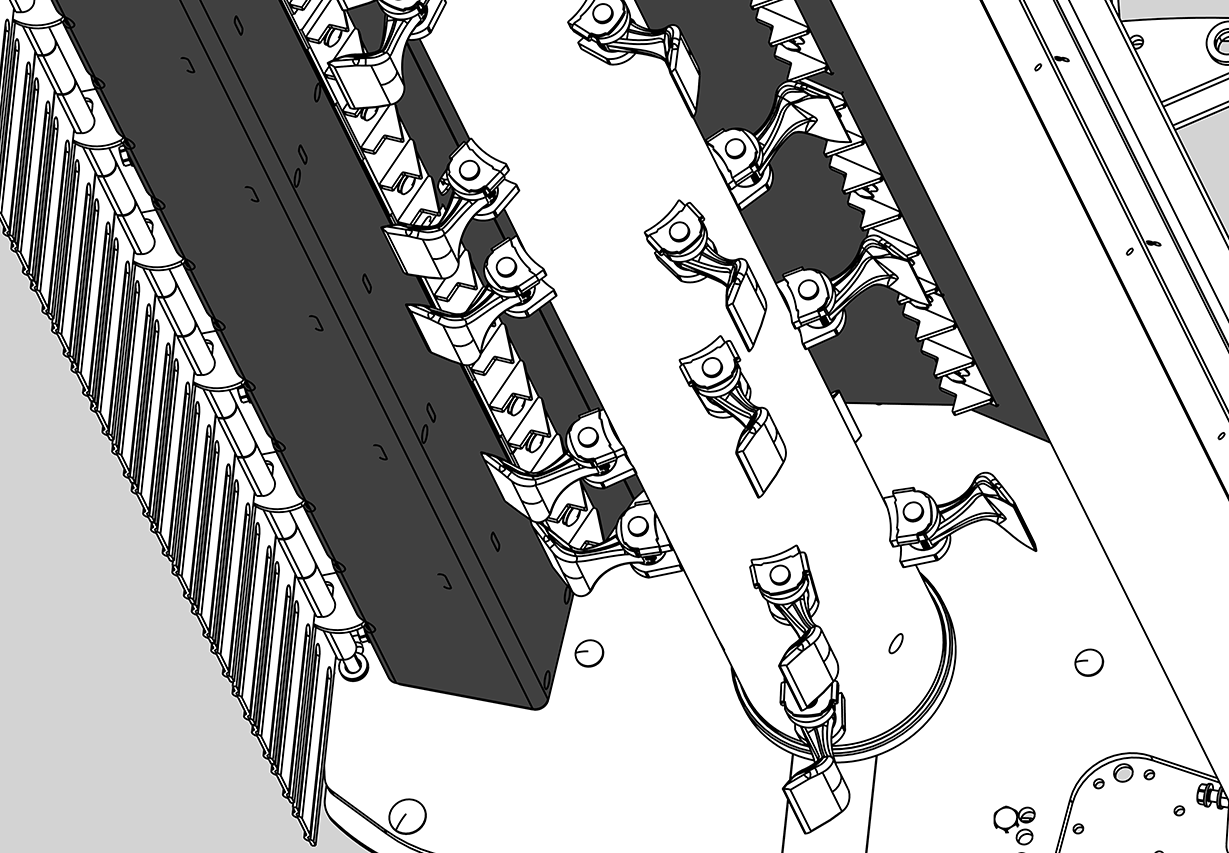

- Purpose-designed counter knives, screwed in three rows

- Floating adjustment of the flail mower units up to +/- 7°

- Gearbox with free wheel 1000 rpm

- Metal flaps

- Warning signs and LED lighting

- Manual opening/closing of the maintenance hood

- Automatic belt tensioning

- Supporting roller

- Two positions of the supporting roller

- Adjustable sweeper arm length

Dodatna oprema

Dodatkowa blacha odporna na zużycie

Dodatkowa blacha odporna na zużycie

The additional wear-resistant sheet metal is screwed onto the flail mower housing and is suitable for work on sandy or rocky terrain.

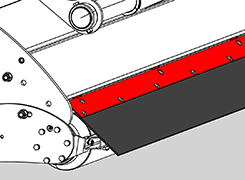

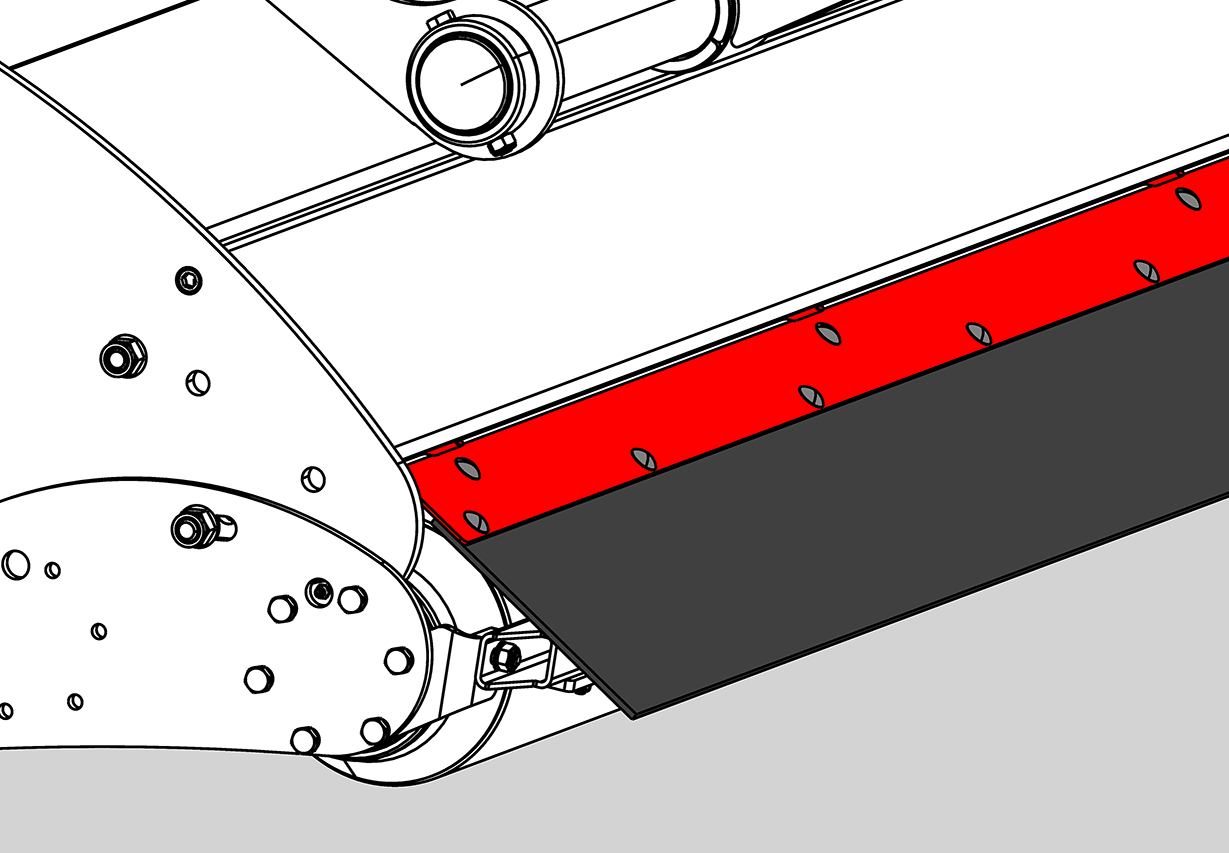

Rubber flap protection

Rubber flap protection

The rubber flap acts as a mechanical barrier that prevents the ejection of smaller particles and dust from the flail mower at the supporting roller. Particularly recommended in combination with double-sided or turnable linkages.

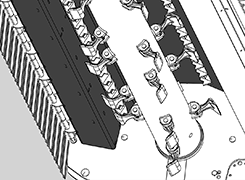

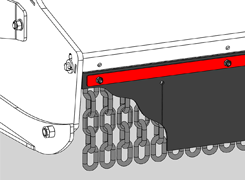

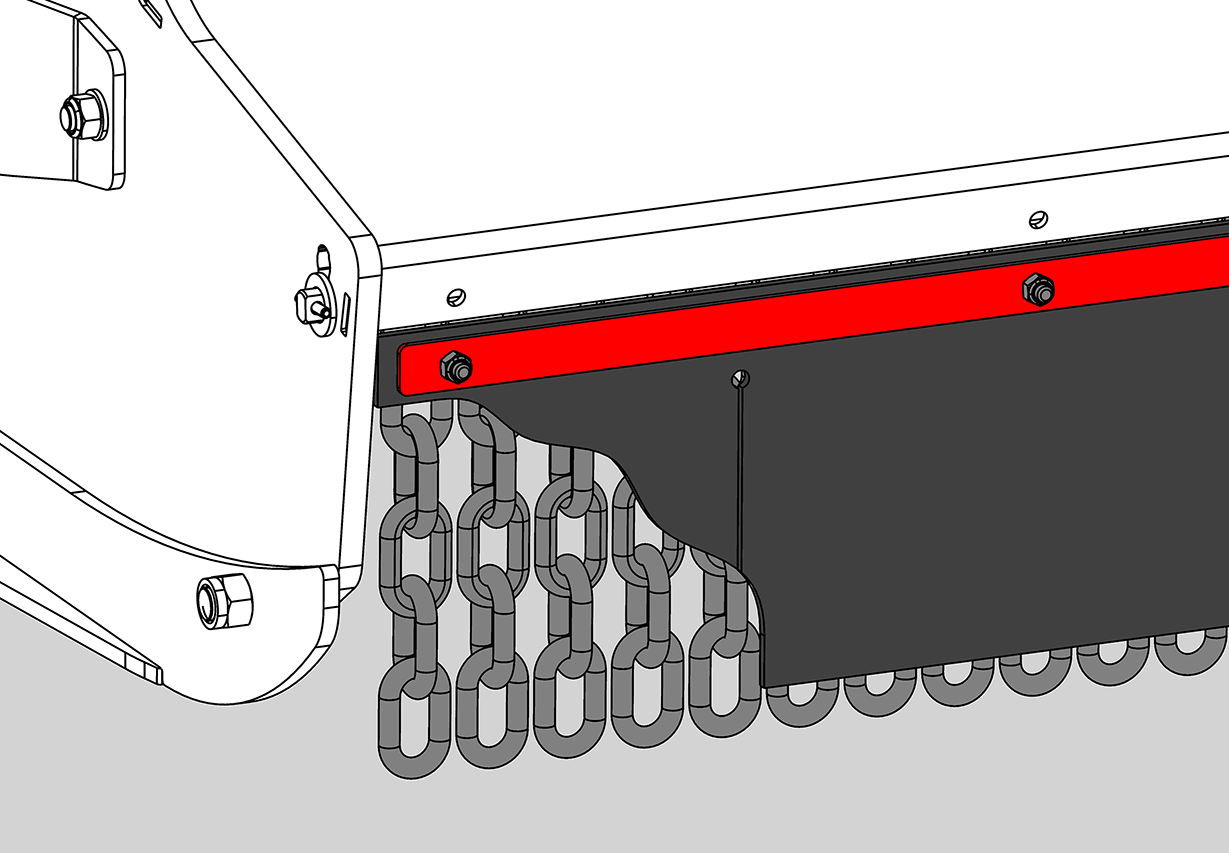

Chains and rubber flap protection

Chains and rubber flap protection

When mulching terrain with a lot of stones, it is advisable to replace the metal flaps with chains and a rubber flap. These are better able to withstand the impact of stones.

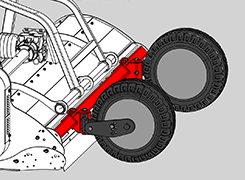

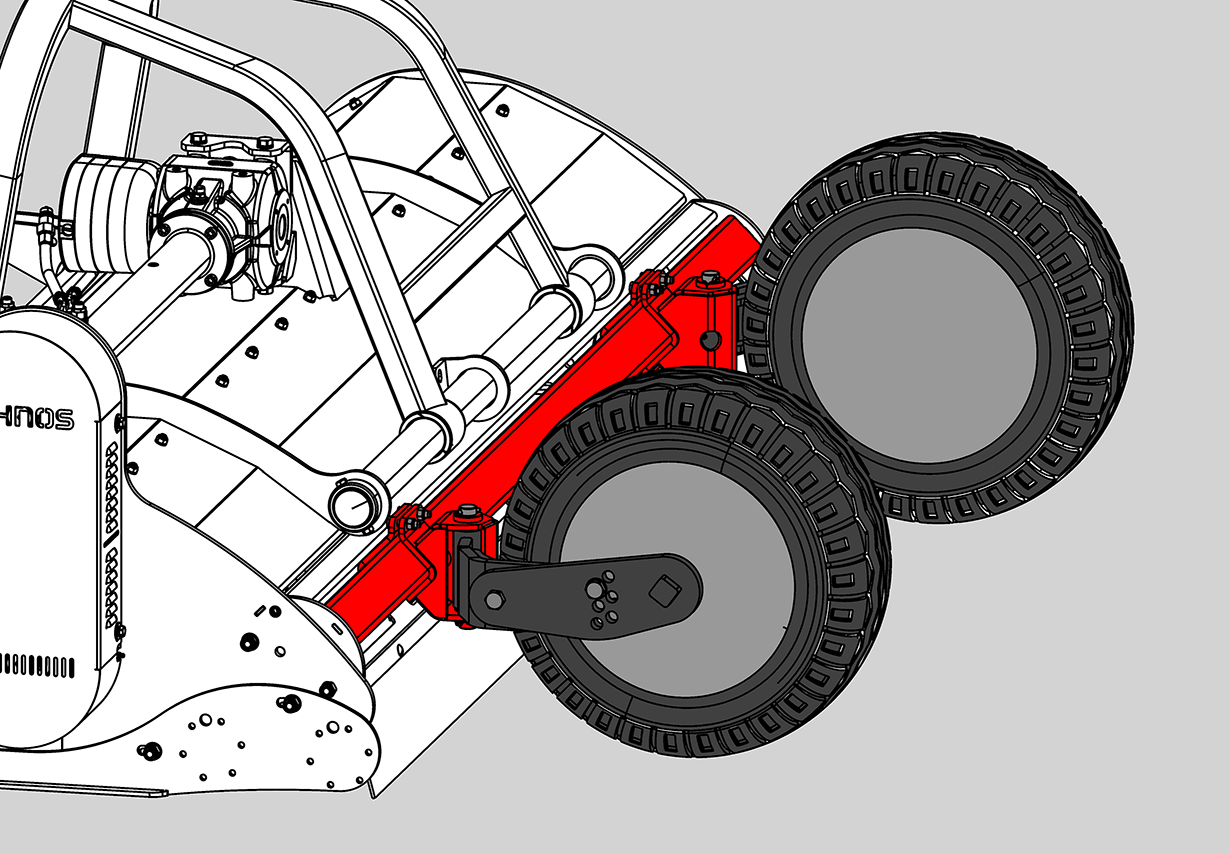

Wheels 12˝

Wheels 12˝

For 12" wheels, the supporting roller is replaced by a bar, on which the two wheel brackets are mounted. The spacing between the brackets can be adjusted as needed. The brackets and 12" wheels are bigger and stronger compared to the 8".

Dodatna oprema

Dodatkowa blacha odporna na zużycie

The additional wear-resistant sheet metal is screwed onto the flail mower housing and is suitable for work on sandy or rocky terrain.

Rubber flap protection

The rubber flap acts as a mechanical barrier that prevents the ejection of smaller particles and dust from the flail mower at the supporting roller. Particularly recommended in combination with double-sided or turnable linkages.

Chains and rubber flap protection

When mulching terrain with a lot of stones, it is advisable to replace the metal flaps with chains and a rubber flap. These are better able to withstand the impact of stones.

Wheels 12˝

For 12" wheels, the supporting roller is replaced by a bar, on which the two wheel brackets are mounted. The spacing between the brackets can be adjusted as needed. The brackets and 12" wheels are bigger and stronger compared to the 8".

The machine features specific advantages designed for optimal use

Patent Low Vib

The Low Vib patent allows for faster rotor rotation with a higher circumferential speed of the flails, significantly enhancing the mulching effect.

Smooth Operation

The patented distribution of the flails on the rotor minimizes vibrations, ensuring smooth operation and extending the flail mower's service life.

Robustness and Durability

The machines are robust and durable, making them suitable for use in more demanding working conditions.

Middle Mulching Unit

The middle mulching unit is designed for cutting material that is not covered by the left and right flail mower units. This solution optimises the working process and ensures an even and thorough mulching, which contributes to improved crop quality.

Massive Forged Flails

The purpose-designed massive flails made of forged steel create air turbulence and a vacuum during mulching, thereby lifting the material from the ground.

Purpose-Designed Counter Knives in Three Rows

The special design of the replaceable, purpose-designed counter knives, screwed in three rows, improves the shredding effect when mulching.

Safe Transport

| The hydraulic hook allows safe transport on the road. |

Drive Protection

The gearbox with free wheel protects the drive of the tractor and enables the use of a traditional PTO shaft.

Adjustable Working Height

The adjustable working height ensures quick and easy support for specific terrain and environmental requirements, allowing the flail mower to perform optimally in different farming conditions.

Two Positions of the Supporting Roller

The inner position ensures faster material flow and thus enables higher working speeds, while the outer position improves the quality of mulching.

Floating Surface Adjustment

The flail mower features floating adjustment to adapt to uneven surfaces, ensuring optimal performance.

Speed Adjustment of the Offsets

The speed of the cylinder offsets is adjusted by setting the hydraulic flow control valves, which allow for precise control of the machine's offset movements.