A Wide Range of Technologies for Optimal Solutions

Our key advantage lies in our expertise with various technologies, including cutting, forming, mechanical processing, welding, and providing high-quality surface protection for metal assemblies through pre-sanding, 9-zone chemical pre-treatment, KTL base coating, and final powder coating. We ensure quality through precise operational control of manufacturing processes, using advanced statistical measurement methods.

Our comprehensive approach, combining various technologies and a strong development team, allows us to offer partners solutions for both improving manufacturing and optimizing final products.

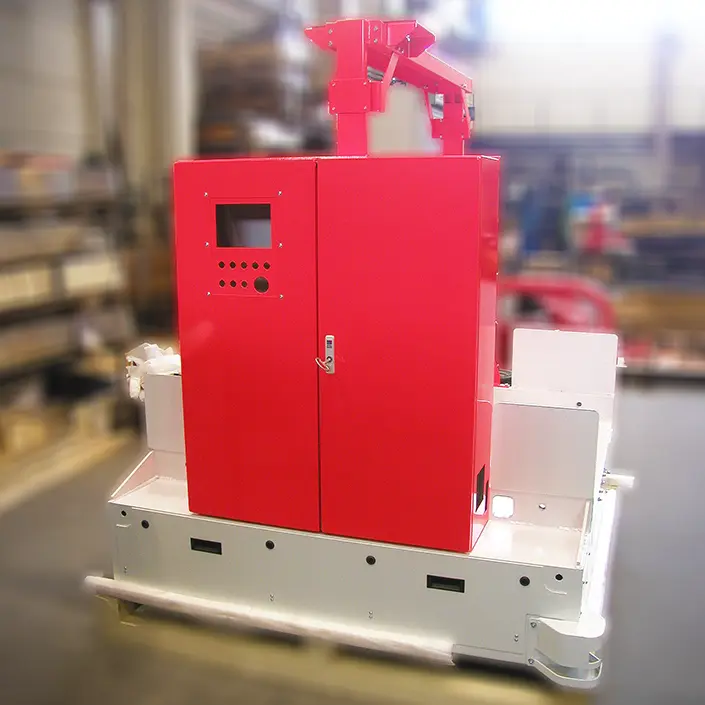

Precision and Automation for Mass and Small-Batch Production

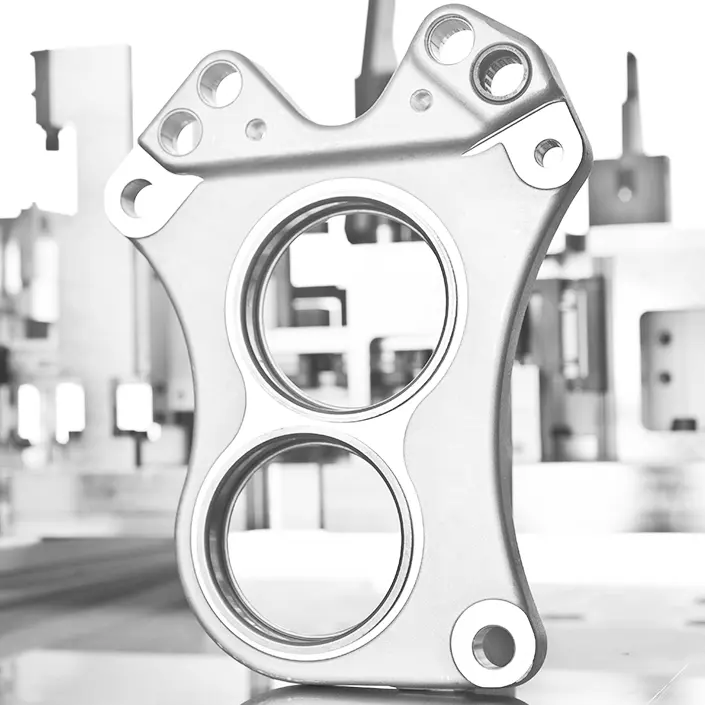

Our modern technological equipment in our robotised production enables us to manage both mass and more demanding small-batch production. We produce various industrial subassemblies and final products, which includes bending complex shapes, sheet metal die forming, machined parts, welded structures, and various kinematic assemblies.

We process and reshape different types of sheet metal, profiles, and tubes made of steel, stainless steel, and aluminum for agricultural machinery, automotive, caravanning, aviation industries, logistics systems, industrial processes, home appliances, and consumer goods.