year 1983

The Beginnings in a Garage Workshop on the Family Farm

The beginnings of our company trace back to a garage workshop on the family farm, where we initially focused on manufacturing tools for the processing of glass, plastic, and rubber.

year 1994

Relocation to a New Location and Technological Expansion

As the original family premises soon proved insufficient, we relocated to a new location in 1994. With the acquisition of Hmezad Strojna, a company that had been manufacturing agricultural machinery since 1980, we expanded our program in the new premises, applying the knowledge and experience we had gained in the field of machine building and agricultural mechanization.

year 2000

Expansion of Production and Office Space and Focus on Our Own Program

At the turn of the millennium, we realized that to achieve greater stability and long-term success, we needed to focus primarily on our own program. This realization led us to lay the foundation for more independent and sustainable growth. We expanded our production facilities and focused on developing our own solutions, specifically flail mowers under our own brand, which provided us with greater flexibility and competitiveness in the market.

year 2009

Entry into the Global Market with Our Own Brand

After several years of product development and testing, increasing production capacity, and upgrading our machinery (CNC technologies, 3D laser, welding robots, surface protection), and, above all, thorough preparations, we confidently entered the global market with our own brand in 2009. This step marked an important milestone in our development as we began expanding our presence in agricultural machinery on an international scale and providing solutions tailored to the needs of global customers.

year 2014

Expansion of Warehouse and Production Facilities with the Introduction of New Technologies

In the years that followed, we focused on improving the surface protection (KTL), developing advanced machines for processing larger areas, and introducing new assembly processes. These efforts resulted in greater efficiency and enhanced production quality.

year 2018

Increase in Production Facilities by More Than

5,000 m²

With the expansion of our production facilities, we reached a new milestone in our development. A key acquisition was the automated storage system for sheet metal cutting and bending, which, along with the purchase of a tube laser, significantly contributes to our production capacity. We also expanded our storage capacities and optimized key processes, enabling us to work more productively and with greater precision.

year 2022

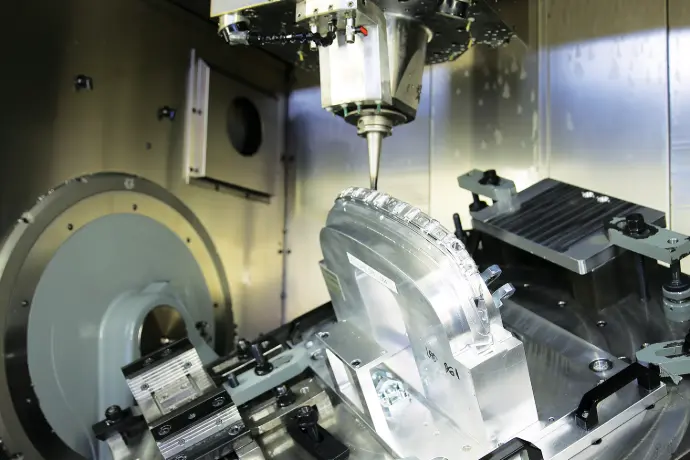

Intelligent CNC Automation

With the purchase of a modern automated storage system for mechanical processing, we made a significant step in automating our processes. This has reduced production times and simplified logistics, increasing productivity and improving the overall production flow. This advancement opens new opportunities for further development and optimization.

year 2023

Sustainability as Our Commitment

At our company, we are aware of the importance of sustainable development and place a strong emphasis on environmental protection. In our pursuit of sustainable solutions to combat climate change, we took another step forward in 2023. We covered the roofs of almost all our buildings with solar panels and launched two photovoltaic solar power plants, which significantly contribute to our energy independence and sustainable future.

year 2025

Further Robotization and Expansion of Capacities for New Market Segments

With the purchase of new smart robotic cells for the production of highly demanding components and a larger 5-axis machine tool, we have significantly enhanced our capabilities. These investments allow us to enter a new market segment, focusing on the production of machinery for municipal technology.